Complex Material Behaviour, Fracture Characteristics & Damage

The constantly increasing requirements for materials continuously set new challenges concerning loading capacity, resistance to damage and crack propagation as well as the characterisation of these properties. In this area MCL counts on its longstanding experience and the combination of state-of-the-art experimental characterisation combined with innovative simulation techniques.

Contacts

In the following a small selection of representative research topics is given that MCL is dealing with in the field of complex material behaviour, fracture characteristics & damage.

Brittle Fracture – Microstructural Constituents

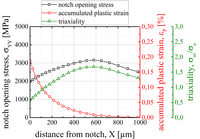

Independent of the application, brittle failure of materials is always undesirable, since it usually occurs without any significant deformation and thus without warning. To avoid brittle failure it is fundamental to reliably identify the failure-relevant microstructural constituents.

The mechanisms of brittle failure and the ductile-to-brittle-transition of steels represent central research topics in several projects in the area of materials engineering at MCL.

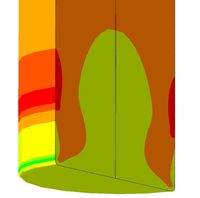

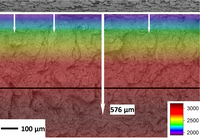

MCL specialises in reconstruction of the real complex loading situations through specific mechanical experiments and visualisation of the resulting load by finite element simulations. That enables the identification of microstrucural constituents most relevant to the failure behaviour, even in materials of very elaborate design.

Cracks in WC-Co Hard Metals

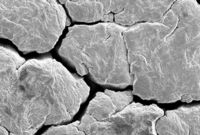

WC-Co hard metals are an important class of hard materials of which structural parts and tools are manufactured. The failure behaviour of hard metals is defect-controlled, i.e. the size of the material inhomogeneities, that they contain like all other materials, is closely linked to their fracture behaviour.

To minimize the size and frequency of defects in hard metals, MCL does research on improvement of manufacturing technologies and surface preparation techniques. This is done in close cooperation with numerous companies and partners from academia such as the Erich Schmid Institute of the Austrian Academy of Sciences, the Institute of Metal Physics and the Institute of Structural and Functional Ceramics – both part of the Montanuniversität Leoben.

Tool Load and Tool Damage

Compared to steels hard metals exhibit a considerably higher resistance to abrasive wear and plastic deformation. This makes them a good choice for the use as tool materials in metalworking tools that have to endure high cyclic loads. The fact that also these very resistant hard metals undergo damage in industrial cutting applications, requires detailed studies of their failure behaviour.

For this purpose, detailed computer simulations of cutting processes such as milling or fine blanking are performed. This helps to quantify the tool loads that act in the most highly loaded tool zones in which tool failure initiates. The acquired information leads to knowledge-based improvements of the tool geometry, the required surface finish and the tool's inner architecture.

![[Translate to Englisch:] Kleine Pore auf einer Bruchfläche aus WC-Co Hartmetall](/fileadmin/_processed_/3/d/csm_02_HMBruch_TKl_e30c60d45b.png)

![[Translate to Englisch:] Wöhlerkurven unterschiedlich bearbeiteter Hartmetalle](/fileadmin/_processed_/8/a/csm_Woehlerkurve_TKl_844c5c261f.jpg)