Industrial metalworking tools are exposed to extreme loads during their application. Constantly growing demands on the tools regarding ever increasing cutting speeds and chip thickness further increase the loads. Therefore, a deep understanding of the interaction between the high-speed steel substrate and the used hard coating is becoming increasingly important. The damage behavior of the substrate/coating composite is therefore decisive for the service life of a tool and thus for the productivity of an industrial manufacturing process.

Recently, the Materials Center Leoben Forschung GmbH (MCL) and the "Laboratory for Machine Tools and Production Engineering" of the Department of Mechanical Engineering of the Aristotle University of Thessaloniki have decided to cooperate in order to specifically investigate this damage behavior.

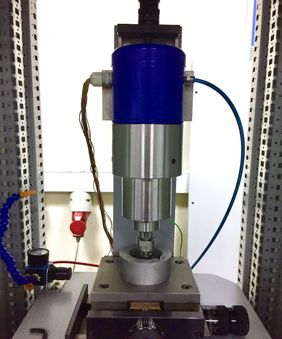

Since the failure originates at the cutting edge, this area is of particular interest. In this region, the load spectrum consists of a combined horizontal and normal load. A test setup developed at the Aristotle University of Thessaloniki, the so-called "Inclined Impact Tester", simulates load spectra similar to those present at a cutting edge in the laboratory. It enables to test different substrate materials consisting of steel or hard metal, in combination with different coatings such as AlCrN or TiN.

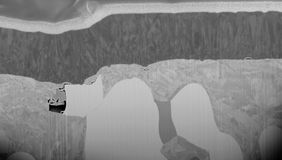

By means of the Inclined Impact Tester, impact loads, which represent a combination of horizontal and normal forces, are applied to coated samples to investigate the early stages of damage of the substrate/coating composite. This damage occurs in the form of crack formation just below the coating within the steel substrate (see cover image).

Impact and effects

By providing information on the type of resulting damage of the substrate, the coating or of the interface between the two materials, it is possible to improve the substrate/coating composite in that way that the failure of coated tools can be delayed, thus extending their service life.

This fact is of economic benefit, as the frequency of changing the tool can be greatly reduced, thus significantly increasing productivity in industrial manufacturing.

Project coordination (Story)

Dipl. Eng. Matthias Gsellmann

Junior Scientist Steel Engineering

Department Materials

T +43 (0) 3842 45922 0

Project partner

voestalpine BÖHLER Edelstahl GmbH & Co KG, Austria

voestalpine eifeler vacotec GmbH, Germany

LMT Fette Werkzeugtechnik GmbH & Co. KG, Germany

Gühring KG, Germany

Aristotle University of Thessaloniki, Greece