Tyre protection chains

Conventional rubber tyres often cannot stand up to the harsh conditions found in steelworks and mining. The rough unforgiving ground combined with the considerable weight of machines such as wheeled loaders and dumper trucks would destroy the rubber tyres within a few days. An economically viable service life can only be achieved by using tyre protection chains. The Austrian chain specialist pewag austria GmbH produces this type of chain in the premium sector under the brand name Tycoon.

Tyre protection chains are designed to protect the face and side walls of the tyre from hostile elements such as high temperatures when driving through hot steel slag or from huge solid rocks and sharp scrap metal. Consequently, these chains are made of a flexible close chain mesh in heat treatable steel. The individual chain links are connected with welded rings to form a chain mesh that safely transfers the high loads and adapts to tyre deformations in service.

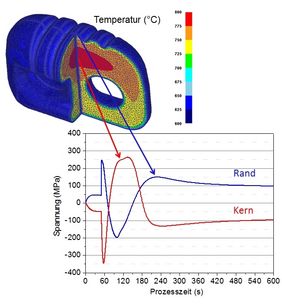

The Materials Center Leoben, Montanuniversitaet Leoben and voestalpine Stahl Donawitz GmbH have supported pewag austria GmbH in the further development of material concepts, process technology and geometry of chain links for tyre protection chains as part of a COMET project. Specific material characterisation experiments and finite element analysis were carried out to investigate the development of damaging stress during the hardening and tempering process. We discovered that lower levels of stress during heat treatment have a direct positive effect on the durability of the chain. The results of the investigation are being incorporated in the on-going development of tyre protection chains in all quality grades.

Hoist chains

Hoist chains are safety-critical components. They must therefore provide not only high load-bearing capacity, but also extreme material toughness and fracture resistance in service. Specific requirements of hoist chains include, for example, adequate fracture toughness at cryogenic temperatures down to –40°C or following exposure to temperatures of up to 380°C. Detailed research studies have examined the factors influencing fracture toughness under these extreme conditions in order to produce hoist chains with appropriate microstructures able to withstand such conditions.

Impact

Together with research partners Materials Center Leoben, Montanuniversitaet Leoben and voestalpine Stahl Donawitz GmbH, pewag austria GmbH has been able to acquire a detailed understanding of the factors influencing the strength and fracture toughness of high-performance chains, successfully apply this knowledge to improve product characteristics and become a leading supplier in the top quality sector.

The results have also played a part in making the pewag Group a leading manufacturer and global player in the field of high-performance and specialised chains, such as hoist chains and tyre protection chains for use in extreme conditions.