Our Range of Services

Static Materials Testing

- Uniaxial tensile test acc. to ÖN EN ISO 6892-1 and ASTM E8

- Tensile test at elevated temperature (up to 900°C) acc. to ÖN EN ISO 6892-2 and ASTM E21

- High- and low temperature tensile test (-150°C to 1400°C)

- 3- and 4-point bending test (also instrumented)

- Uniaxial compression test and cylinder compression test

- Compression test at elevated temperature

- Notched bar impact bending test / impact bending test (-100°C to 500°C) acc. to ÖN EN ISO 148-1

Fracture Mechanical Testing

- Fracture toughness KIC acc. to ISO 12737/ASTM E 399

- Fracture mechanical tests acc. to ISO 12135/ASTM E 1820, J-Integral (JIC and J0,2BL; CTODIC and CTOD0,2BL, Jda-curve and CTODda-curve)

Cyclic Materials Testing

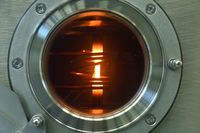

- Low cycle fatigue tests (uniaxial, torsion, tensile/compression/torsion) on metallic materials up to 1500°C (strain based approaches to total fatigue life, ratchetting, …) in air, inert gas, vacuum

- S/N tests (tension/compression, bending pulsating test)

- Dynamic component tests (e.g. fatigue strength of bolts)

- Special cyclic tests (blocked tests (heating / cooling / superposition with mechanical loading (tension/compression/torsion))