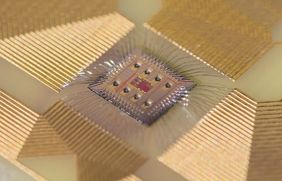

The goal of the project NanoSense was to develop and fabricate chemical nanosensors based on ultrathin SnO2 films as sensing layers. The gas sensors are functionalized with highly specific mono- and bimetallic Au/Pt-nanoparticles in order to detect the toxic gas carbon monoxide (CO) in the concentration range 1 – 50 ppm in ambient air.

The Materials Center Leoben (MCL) is prototyping chemical sensors based on SnO2 sensing layers for CO and other target gases, which are integrated on CMOS-based micro-hotplate devices enabling heating of the gas sensitive layers up to operation temperatures of 400°C.

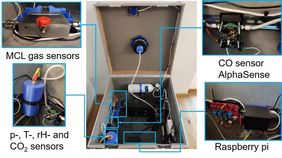

Based on MCL-own chemical sensors as well as on commercially available gas sensors a test box has been designed and setup, which enables in-field CO detection and measurements of other environmental parameters in harsh environmental conditions (Fig.1).

The test box provides the following features:

- Gas sensors for CO developed at MCL,

- Commercially available sensors for temperature, air pressure, humidity and CO2, CO (for comparison purposes), and Volatile Organic Compounds (VOCs),

- Raspberry pi microcomputer for data acquisition, evaluation, and visualization,

- CO-reservoir for repeated (once per week) on-board calibration of the CO gas sensor,

- Implementation of “traffic light” LED concentration indicator (green/yellow/red) showing the CO level according to the maximum admissible concentration values.

The test box can be further expanded in functionality by adding other MCL gas sensors for VOCs and H2S, for example.

Impact and effects

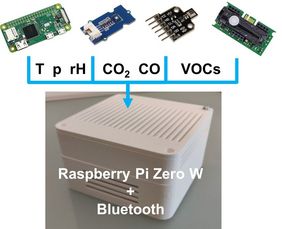

Based on the test-box, a miniaturized sensor platform has been developed (Fig.2), which provides all functionalities of the big test box. Additionally, this sensor platform includes a Raspberry pi microcomputer for data processing, storage, and visualization, as well as Bluetooth-connection for wireless communication and Internet-of-Things (IoT) capability.

The housing (size 10 x 10 x 6 cm2) has been designed and fabricated by 3D-printing, six sensor platforms have been prototyped. Goal is to setup a sensor network in the rooms of MCL and to perform air quality monitoring in real life conditions.

The sensor data will be accessible for every employee using a smart phone, for example, to display the data. In a later stage the commercial sensors will be replaced by the highly miniaturized MCL-own multi gas sensor devices, which has been developed within the FP7-project MSP (GA No. 611887) and are fully integrated in CMOS devices.

In the future these sensor platforms will be also employed for outdoor environmental monitoring.

Project coordination (Story)

Univ.-Doz. Mag. Dr. Anton Köck

Key Researcher

Department Materials for Microelectronics

T +43 (0) 3842 45922-505

anton.koeck(at)mcl.at

Project partner

Montanuniversität Leoben, Chair of Functional Materials and Materials Systems, Leoben, Austria

Montanuniversität Leoben, Chair of Chemistry of Polymeric Materials, Leoben, Austria