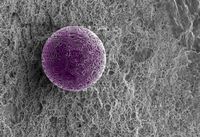

Cross-beam scanning electron microscope with focussed ion beam (FIB) from Zeiss (AURIGA®-CrossBeam® Workstation):

- High resolution field emission scanning electron microscope with various detectors (secondary electron, backscattering electron, STEM, secondary ion, in-lens and EBSD detector)

- Focussed ion beam (Cobra-Orsay-Physics)

- Gas injection system for different substances (for deposition of graphite or platinum, for etching by means of iodine and water vapour) and charge compensation for analysis of non-conducting specimens

- Energy dispersive X-ray analysis system (EDX)

Scanning electron microscope with large specimen chamber from Zeiss (EVO MA 25®):

- Scanning electron microscope with LaB6 cathode and low pressure mode (also suitable for analysis of non-conducting and contaminated (e.g. oil contaminated) specimens

- Large sample chamber for the analysis of components and large specimens: specimen weight with full tilting capability up to 2.5 kg, specimen height up to ~ 100 mm; specimen weight without tilting > 5 up to ~ 10 kg (max. height up to ~ 210 mm)

- Secondary and 5 quadrant backscatter electron detector

- Energy dispersive X-ray analysis system (EDX)

- 3D surface topography software from Alicona (MeX)