Materials Design and Characterisation

A detailed knowledge of the correlations between the microstructure, the mechanical and the physical properties is fundamental for the design of innovative materials. To develop new materials, MCL performs numerous research projects with scientific and industrial partners investigating the structure-property relationships of various material classes.

Currently, MCL investigates the following material systems:

- Tool steels

- Bainitic steels

- Precipitation hardening (PH) steels

- Duplex steels

- Highly alloyed martensitic / austenitic steels with excellent strength, toughness and ductility

- Powder metallurgically produced steels with high hard phase fractions

- Hard metals

Contacts

In the field of materials design and characterisation the research foci comprise, among other things, the following topics:

Alloy Development

The conception of new alloys and material systems represents extremely complex tasks, that require profound experience in this field.

For this purpose, MCL's approach lies in coupling detailed microstructural investigations with testing of the relevant mechanical properties of existing materials to establish a fundamental understanding of the structure-property relationships of the regarded material category. Based on these findings thermodynamic and kinetic simulations as well as tools developed in our research area "Atomistic Modelling" are applied to predict the properties of new material systems.

An example topic of our research work is the development and improvement of hard and extremely wear resistant tools. For the tools, our interest is focused on both the development of the substrate material as well as the development of suitable surface treatments and hard coatings.

Austenite Stability

Many novel, extremely ductile or tough steels exhibit effects such as transformation induced plasticity (TRIP), twinning induced plasticity (TWIP) or transformation toughening. Essential for all these phenomena is the stability of usually finely distributed austenite in ferritic or martensitic matrices. Generally, the stability of the austenite represents the resistance against transformation into hard and brittle martensite.

In that area, MCL's research activities concentrate on the investigation of austenite stability. By means of multi methodical approaches consisting of dilatometry, diffractometry, high resolution imaging methods and mechanical tests we are capable of investigating the effects of the austenite transformation behaviour on toughness, strength and ductility in detail. Additionally, techniques are developed to in-situ evaluate the austenite to martensite transformation by mechanical loading (e.g. in-situ tensile tests).

The results of the stability investigations are then used to develop new alloy systems exploiting the effects named above, according to the application and the resulting mechanical loading.

Precipitation Behaviour

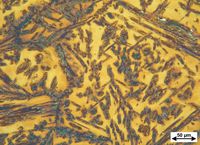

Generally, the microstructure of metals significantly influences their mechanical properties. Therefore, the analysis of the microstructure is regarded as fundamental for the improvement of these properties.

In current projects for example, the inital stages of carbide formation during tempering and the influences of heat treatment process control and mechanical deformation on precipitates, bainite and martensite formation as well as stress evolution within the microstructure are investigated.

For the selective analysis of the usually nm-sized microstructural constituents, MCL cooperates with scientific partners, e.g. with the Erich-Schmid Institute of Materials Science or the Department of Physical Metallurgy and Materials Testing to perform transmission electron microscopy and atom probe investigations.

In order to predict microstructural processes, experimental results of the microstructure investigations are also provided for the further development of the thermodynamic/thermokinetic simulation software MatCalc. The software development is carried out in cooperation with the Institute of Materials Science and Technology at the Technical University of Vienna.

![[Translate to Englisch:] EBSD-Aufnahme gehärteter Vergütungsstahl (Martensit)](/fileadmin/_processed_/9/f/csm_NO-10-3A_neu_02_IPF_a22ad0b28f.jpg)

![[Translate to Englisch:] TEM-Bild mit sehr feinem Austenitfilm in martensitischem Stahl](/fileadmin/_processed_/9/b/csm_01_RA_DissMGr_BF_03d88cde96.gif)

![[Translate to Englisch:] Atomsonde-Messung eines ausscheidungshärtenden Stahls inkl. MatCalc-Simulation des Ausscheidungsvorganges](/fileadmin/_processed_/0/6/csm_01_APT_SIM_e8b76635c5.gif)