Steel - Innovations of the MCL

"Materials and Manufacturing Technologies for the Benefit of our Customers."

Steel is available in thousands of forms and qualities which makes it ideal for a huge variety of applications. Although steel is sometimes considered an "old" material, thanks to its versatility its potential is by no means exhausted. The MCL understands steel in all its forms, right down to its atomic structure, making us the ideal partner when it comes to lending this complex materials group new and innovative facets.

Extending Diversity

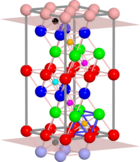

Whether we’re looking for something new or trying to improve what we have: only with a sound, theoretical and comprehensive understanding of steel in all its manifestations can we achieve our goals to develop new products for the benefit of our customers, optimizing factors such as energy, material and time input in the manufacturing process, or improving service life and durability. Using state-of-the-art technical equipment, MCL is able to characterise the structure and properties of steel at all length scales, from microscopic samples through to complete components. MCL researches steels right down to their atomic level using high-performance computing infrastructure which enables state-of-the-art simulations to a standard previously undreamed of. MCL offers the highest levels of expertise in basic and applied research, focusing on the simulation of steels both in the manufacturing process and in service.

Expertise

"Why we simply know more."

MCL’s expertise in the field of steel is based on the following pillars:

- Long years of steel research coupled with the traditional expertise of Montanuniversitaet Leoben

- Continuous collaboration with leading steel manufacturers, processors and users in different industrial sectors

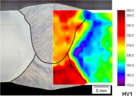

- State-of-the-art laboratory equipment and analysis methods

Development

"Reinventing steel every day."

The MCL laboratories provide the foundations for the development of innovative steels for specific applications. A wide range of optimisation processes is available depending on customer requirements:

- Improving material properties such as maximum strength or toughness and physical properties such as thermal conductivity and expansion

- Cost reduction through resource efficiency in the manufacturing process and shorter process chains, e.g. for novel age-hardening steels

- Design of steels that open up new fields of application

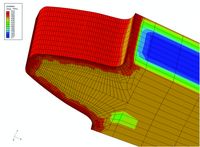

The process chain simulation of hardness and residual stress distributions allows the calculation of permissible local stresses. The component and manufacturing process can be optimised in an iterative process.

Manufacturing and Process Chains

"We make steel manufacturing more efficient and environmentally-friendly."

Our focus in the further development of processing chains for steels and steel composites lies on:

- Modification of steels aimed at optimising their processing behaviour

- Simulation-based optimisation and shortening of process chains in terms of production efficiency, quality and resource use

- Support of intelligent production control concepts using physically-based process models

Use of Highly Complex Components

"We direct atoms to ensure their perfect interaction in service."

The MCL has a recognized expertise in the experimental analysis and simulation of the behavior of highly complex components:

- Stress and fracture mechanics analysis for new design concepts

- Fitness-for-purpose and damage-tolerant-design-concepts

- Thermo-mechanical fatigue (TMF)

- Multiaxial loading

- Load bearing capacity and fatigue behaviour of inhomogeneously structured components (e.g. welded structures)

- Graded materials and material composites

- Modelling of complex material and damage behaviour

Examples

"With our customers and partners we are changing the world."

The MCL provides fundamentals, simulations and experimental results for

- Weight optimised components for extreme load conditions, e.g. for generator parts or rail vehicles

- Customised solutions for advanced inhomogeneously structured steel products, e.g. novel material concepts for rail switch points or tyre protection chains for utility vehicles in the steel industry

- Innovative design of high-strength steels, e.g. tool steels for stamping and fine blanking or high-performance steels for roller bearings

- New material and process concepts designed to reduce manufacturing steps, e.g. new precipitation hardening steels for high-performance automotive components