When one thinks about ceramics, the first associations which often come to our minds are pottery, fine porcelain, tiles for the roof and floor, and even bricks. However, ceramic materials are also widely employed in all sorts of electronic devices that surround us. Most prominently, ceramics are used in capacitors – one of the basic building blocks of electric circuits, whose purpose is to store charge and ultimately to store energy.

There is an ongoing effort to improve ceramic materials for energy storage to push the limits of their performance and make them more environmentally friendly, for example by finding new compositions that do not contain lead. Here, a deep understanding of the chemistry and structure down to the atomic level is critical. This knowledge can be gained using Raman spectroscopy in conjunction with theoretical methods for predicting Raman spectra. In this approach, the ceramic under investigation is irradiated with laser light and the scattered light is analyzed. The latter contains unambiguous information about the chemical composition and the way in which the atoms are bonded together.

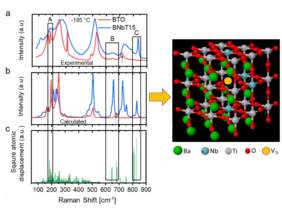

Structural properties such as phases, atomic defects and residual stresses leave their "fingerprints" in the Raman spectrum in the form of specific spectral features. However, the unambiguous assignment of a measured feature to a specific structural property is very challenging. This is where the calculation of Raman spectra using density functional theory (DFT) can make an invaluable contribution.

So far, this approach was mostly developed for the prediction of spectra for single crystals. Ceramic materials, however, consist of small crystallites, hence an averaging procedure is required to predict the spectra appropriately. The standard approach for computing Raman spectra of ceramics used before did not take into account important features of polar materials that are highly relevant for electroceramics. Hence a new method called the “Spherical Averaging Method” has been developed at the Materials Center Leoben (MCL).

This method has significantly improved the predictive power of theoretical Raman spectroscopy, especially, when applied to polar ferroelectric ceramics, like barium titanate (BaTiO3). Fig. 1 shows an example of atomic defect detection in barium titanate using our method. When this material is doped with niobium (Nb), the measured spectra change. The predicted Raman spectra using our new method allow to unambiguously identify the atomic origin of these changes: They originate from Ti vacancies that form due to Nb addition.

Impact and effects

The method developed at MCL extends the possibilities of theoretical Raman spectroscopy of ceramic materials. It allows deciphering complex spectral features, e.g. peak asymmetry, and clearly relates the measured features to structural properties. In addition, computer software - the Spherical Raman Evaluator (SpheRaE) - has been developed to facilitate the application of the method and to automate the modeling procedure.

Project coordination (Story)

Priv.-Doz. Dr. Marco Deluca

Deputy Group Leader Sensor Solutions

Materials Center Leoben Forschung GmbH

T +43 (0) 3842 45922-530

marco.deluca(at)mcl.at

Project partners

• CNR-ICMATE, Italy

• Czech Academy of Sciences, Czech Republic