Tool technology meets material knowledge

At the Materials Center Leoben, research into ultra-high-strength tool materials such as high-speed steels and hard metals is an important focus of research. The aim of the research is to understand the stress and damage behavior of tools in industrial manufacturing processes.

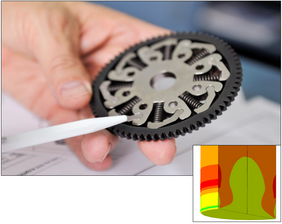

The project A5.18 focused on improving the properties of fine blanking tools. As with cookie cutting, a punch (cookie cutter, see picture above) with the contour of the desired part (cookie) is pressed through a steel sheet (dough). A typical fine blanking part is the steel eyelet of the seatbelt for the seatbelt in the car or the assembly shown above, a slipping clutch of a drilling machine.

In order to understand the deformation and damage mechanisms in fine blanking tools, the project implemented a decisive improvement in the computer simulation technology available to date with regard to the deformation of high-strength tool materials. The development of tensile residual stresses in the tool due to repeated plastic deformation of the cutting edge can now be calculated reliably. The results show that the build-up of damaging tensile residual stresses in tools can be suppressed if the much stronger tungsten carbide hard metal is used as the tool material instead of steel. This reduces the tensile stresses in the tool and only those remain which always occur when a punch is pulled out of the cut steel (see red zones in the picture above). These tensile stresses lead very early to crack formation and tool breakage, especially if tools show too large surface defects after their manufacture.

In cooperation with researchers from the precision cutting industry and the application of MCL's knowledge on the crack growth behaviour of high-strength materials, it has now been possible to replace the previously used tool material steel with the much stronger but also more tension-sensitive hard metal. Tungsten carbide hard metal is the hardest construction material in the world and has so far been used primarily in wear protection applications and for drills and milling cutters for machining metal and wood. As a result of the project, tungsten carbide hard metal can now also be used for cutting dies of fine blanking tools.

Impact and effects

The use of tungsten carbide hard metal for fine blanking punches and dies has enabled the process limits for fine blanking processes to be significantly extended. Tungsten carbide hard metal tools can now be used to fine-cut sheets that could not be machined with steel tools because they were too thick. Depending on the complexity of the component geometry, the tool life could be increased to 15 - 65 times that of steel tools.

The described project creates an effective implementation of theoretical concepts directly in manufacturing companies. It expands the toolmaking and manufacturing competence of the participating partner companies and the Materials Center Leoben. The increase in productivity achieved in the fine blanking industry secures jobs and added value at the high-wage production location of Europe, which is in global competition. The findings from the project were presented in five scientific publications.

Project coordination

Dr. Thomas Klünsner

Group Leader Hard Metals

Materials Center Leoben Forschung GmbH

T +43 (0) 3842 45922 - 0

thomas.kluensner(at)mcl.at

Project partner

Welser Profile, Austria

Fritz Schiess AG, Switzerland

CERATIZIT Austria GmbH

Platit AG, Switzerland