Since the results obtained in research projects are often in the form of methods, analytical solutions, program codes (scripts) or even tables, an application of these results for project partners or interested parties outside of the respective projects is sometimes difficult or even only possible with in-depth knowledge in the corresponding field of activity. That’s the reason why Materials Center Leoben (MCL) made the decision to increasingly integrate project results into user-friendly software tools. These software tools work independently of commercial program packages and external program libraries.

The MCL is thus placing greater emphasis on the broad exploitation of research and project results and this strategy is already bearing its first fruits, as will be shown exemplary by three representative software tools developed on basis of research results achieved in several multi-firm and strategic COMET projects and in follow-up internal development activities of MCL.

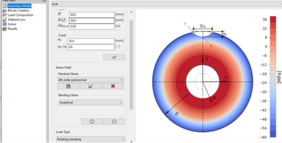

INARA - Integrity Assessment for Railway Axles

Based on experimental results, a crack growth model was developed, able to predict the behavior of semi-elliptical cracks in wheelset shafts even under non-monotonous loads (curves, uphill travel). This crack growth model was integrated into the software tool INARA (Integrity Assessment for Railway Axles), which can now be used to assess the influence of load sequence effects on crack propagation. INARA is also able to predict the growth of fatigue cracks under user-defined 2D stress distribution in a railway axle cross-section under the influence of axisymmetric residual stresses. In the meanwhile, INARA is not only used by former project partners, but has also been licensed to some European railroad operators - further inquiries are in progress.

Apart from software tools for products, as shown with the example of the wheelset axle, also software solutions for significantly smaller scales have been developed, namely software for material development.

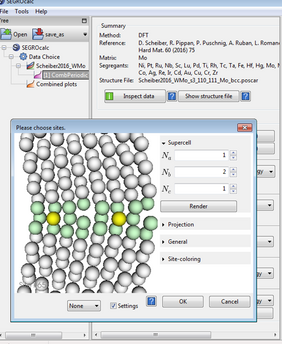

SEGROcalc – Grain boundary design tool

The SEGROcalc software tool was developed to predict grain boundary segregation and its effect on material properties. SEGROcalc can be used to calculate segregation at grain boundaries in metals in order to draw fundamental conclusions about grain boundary-dominated properties of materials (formability, strength, hydrogen embrittlement, diffusion, grain growth, precipitation and much more). The software allows the calculation of the time evolution of the concentration of alloying as well as impurity elements at grain boundaries as a function of temperature and the resulting effects on the grain boundary properties. This allows not only a targeted design of properties but also the computer-aided design of heat treatments. The central parameter, the segregation energy, is obtained from a database, whereby values from experiments, phenomenological models or from high-precision atomistic modelling are available.

GreenALM - High-throughput ab-initio solver

With GreenALM, MCL has developed a highly efficient ab-initio solver for the specific purpose of ab-initio-based high-throughput alloy development. GreenALM (Green's functions based Alloy Modeling) is a software toolkit based on density functional theory with a Green's functions approach. It is especially efficient and versatile for the calculation of chemically and magnetically complex alloys, including random multicomponent alloys and paramagnetic systems. In addition, GreenALM provides a workflow for calculating the thermodynamics of alloys.

Demo versions of the three software tools as well as other software solutions can be found on the MCL homepage (www.mcl.at/software).

Project coordination (Story)

Dr. Jürgen Maierhofer

Group Leader Computational Product Reliability

Department Simulation

T +43 (0) 3842 45922 – 41

juergen.maierhofer@mcl.at

Project partners:

Several scientific and company partners were involved in the development of the software tools.