Printed circuit boards (PCBs) are one of the main parts of any electronic device. They serve as carriers for data-processing components and transmit electrical signals from A to B. The production of PCBs involves several manufacturing steps. One of the most important sub-processes is the etching of copper foils with different kinds of solutions, where dispensable copper is dissolved to obtain defined conductor paths. Because of the ideal properties the most common used liquids are based on acidic chloride solutions containing copper ions.

At the Chair of Nonferrous Metallurgy at the Montanuniversity of Leoben, an experimental setup was realized which enables a detailed investigation of the etching processes applied in the industrial production of printed circuit boards by the partner company AT&S.

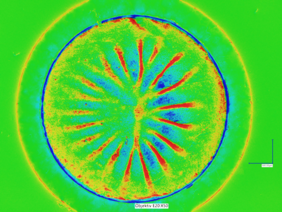

During the reaction of copper and the electrolyte, which contains reactive ions like Cl-, Cu2+ and Cu+, different copper chloride complexes occur. These compounds can be identified as solid CuCl on the metal surface and dissolved CuCl ions.

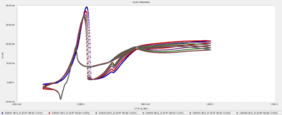

More information about the reactions is provided by the application of voltammetric methods. In a three-electrode system, a copper sample is installed in a rotating working electrode, a so-called rotating disk electrode (RDE), and polarized over a defined potential range.

The detected characteristic currents can be assigned to chemically reversible and irreversible reactions. A variation of the parameters temperature, concentration of reactive ions and fluid flow exhibits the effects on the Cu-Cl system. The recorded voltammogramms offer achievements about reaction kinetics which can be used in process simulations.

Impacts and effects

With the help of the obtained knowledge about properties of ions and copper chloride complexes involved in the copper dissolution, it will be possible to simulate the etching process on the computer and predict specific reactions.

These computer models will assist in optimizing the PCB manufacturing process towards more sustainable use of etchants and higher precision of the process.

Projekt coordination (Story)

DI Dr.mont. Eva Gerold

Montanuniversity of Leoben

Chair of Non-Ferrous Metallurgy

T +43 (0) 3842 402 5207

eva.gerold(at)unileoben.ac.at

Project partners

• AT & S Austria Technologie & Systemtechnik AG, Österreich

• Montanuniversity of Leoben, Chair of Non-Ferrous Metallurgy, Austria