For many materials, the thermal conductivity values of thin layers and the interfacial surfaces between them, which are only a few nanometers thick, can differ greatly from the values of the same material with a larger extension. In microelectronics and tooling, thin films and their ability to dissipate heat are of great importance. For the characterization of such thin film systems, special measurement techniques are needed, such as the Time-Domain Thermo-Reflectance (TDTR) method. Within the scope of the project, on the one hand knowledge about thermal conductivity values of the above-mentioned systems was generated, on the other hand the commercially available TDTR (PicoTR, Netzsch Gerätebau GmbH) method was optimized and extended with respect to the evaluability. The latter resulted in a semi-automated evaluation tool that minimizes operator-induced uncertainties.

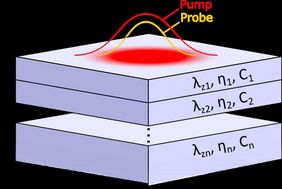

In close cooperation with Netzsch Gerätebau GmbH Germany and Netzsch Japan K.K, the reproducibility of the measurement data for e.g. semiconducting and metallic thin films for microelectronics was analyzed. The newly developed evaluation methodology was verified and also the measurement uncertainties resulting from the evaluation were quantified. The modularity of the TDTR method and the measurable layer thicknesses were also extended in the course of the project. The accuracy of these extensions was verified with the aid of sensitivity studies. The TDTR methodology itself is based on the principle of thermo-reflection, in which an optically reflective layer of metal with known temperature dependence of its reflectivity is used to determine the temperature of the surface irradiated with a heating (pump) and a measuring (probe) laser pulse. In the project, an optimally reflective metal layer made of molybdenum that can be used reliably at elevated temperature was produced.

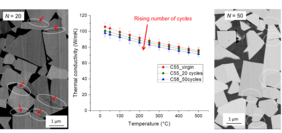

In cooperation with Ceratizit Austria, investigations were carried out concerning changes in the thermal conductivity of hard metals in their application environment. Such carbides are used for metalworking tools such as drills and milling cutters, whose cutting edges are subjected to high mechanical load and temperature during use, creating defects in the carbide. It was investigated how the accumulation of these defects affects the ability of cemented carbide to dissipate the heat generated during metalworking. The higher the number of mechanical load cycles applied to laboratory specimens at 800°C, the lower the thermal conductivity of the carbide.

This effect could lead to self-accelerated aging of the material, since the heat generated at cutting edges can be dissipated more poorly and thus causes the tool material carbide to "age" more quickly.

Impact and effects

Thanks to the project and the associated know-how and methodology development, the measurement of the thermal conductivity of thin films can now be offered as a contract measurement at MCL. This is done via the newly developed evaluation tool, which has less uncertainty in the analysis and provides a quantified error analysis.

Project coordination (Story)

Dr. Barbara Kosednar-Legenstein

Laboratory Manager Microelectronics

Materials Center Leoben Forschung GmbH

T +43 (0) 3842 45922-49

barbara.legenstein(at)mcl.at

IC-MPPE / COMET-Zentrum

Materials Center Leoben Forschung GmbH

Roseggerstrasse 12

8700 Leoben

T +43 (0) 3842 45922-0

mclburo@mcl.at

www.mcl.at

Project partners

• Montanuniversität Leoben, Österreich

• Ceratizit Austria GmbH, Österreich

• NETZSCH-Gerätebau GmbH, Deutschland

• NETZSCH Japan K.K