Particulate matter and fine dust in our environment are a huge threat for the human health. Thus, miniaturized particle sensor devices are of great interest to enable individual monitoring of air quality and to detect potentially harmful situations.

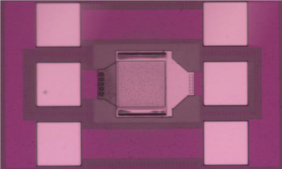

Within the project “ParticulateMatterSensor”, three different particle sensor principles have been investigated: The University of Warwick (UK) has developed a sensor principle based on frequency shift of thin film solidly mounted resonator (SMRs) devices. Such a device integrated with a CMOS circuitry is shown in the picture above. MCL has been developing sensor devices based on thermal cooling of CMOS integrated µhp devices. Moreover, the suitability of MOx-based chemical sensors for particle detection has been evaluated.

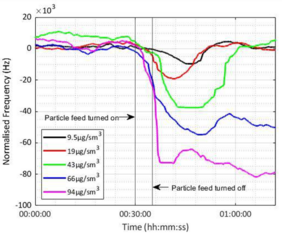

Several generations of devices have been developed. A final setup integrating all three major components (1), (2), and (3), has been successfully realized at the University of Warwick. A measurement result demonstrating the successful proof of principle of the total integrated sensor system is shown in Fig.1: The frequency shift of the SMR sensor increases with a growing concentration of particles. Additional operation of the “particle pump” - that was patented by MCL and is based on forced convection - significantly enhances the measurement signal of the SMR particle sensor.

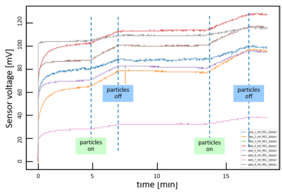

For demonstrating the proof-of-principle of thermal cooling of the µhps, MCL has employed its own conductometric, CMOS integrated chemical sensors, which employ an ultrathin (50 nm) SnO2 film as gas sensing element.

The experiments showed that the thermal cooling principle works only at very high particle concentrations. The chemical sensors rely on interaction of gas molecules with oxygen atoms at the surface of the SnO2 films. In order to check the feasibility of this sensing principle for particle detection, MCL operated the chemical sensor devices and exposed them to particles. Fig.3 shows the voltage behavior of 7 different sensors integrated on a single chip at an operation temperature of 100°C.

The measurements demonstrate a clear correlation between particle flow and concentration, and the resistance of the SnO2-thin films. Thus, chemical sensors can be also employed as particle sensors!

Impact and effects

Air pollution is a major environmental risk that causes more than 3 million deaths worldwide every year. The fact that the chemical sensors can also be used as particle sensors and integrated on a CMOS chip opens up completely new possibilities, such as a measurement of critical indoor air values; for example oxygen and carbon monoxide content together with the measurement of fine dust particles on a wristband. An already built demonstrator, which is used in a wristband application, comprises a total of 57 sensors - a worldwide unique sensor system.

Project coordination (Story)

Univ.-Doz. Mag. Dr. Anton Köck

Group Leader Sensor Solutions

Department Microelectronics

T +43 (0) 3842 45922-505

anton.koeck(at)mcl.at

IC-MPPE / COMET-Project

Materials Center Leoben Forschung GmbH

Roseggerstrasse 12

8700 Leoben

T +43 (0) 3842 45922-0

mclburo@mcl.at

www.mcl.at

Project partner

• University of Warwick, UK