Artificial intelligence (AI) is the umbrella term for self-learning systems and is being researched at the Materials Center Leoben (MCL) (IC-MPPE project Hybrid 2.0) as well as applied to accelerate the development of new high-performance materials (IC-MPPE project MCacceL). One focus is on steels with a so-called bainitic microstructure. These types of steels have the potential to save energy and thus CO2 emissions during production, as they require fewer heat treatment steps than comparable conventional steels.

AI-supported steel design begins with the definition of target variables and setting variables in the design space. The target variables describe the characteristic values of the material that are to be optimized. In the case of bainitic steels, these are yield strength and uniform elongation. The setting variables refer to parameters with the help of which the target variables can be optimized, such as chemical composition and heat treatment parameters. In the current project, the contents of the alloying elements carbon, silicon, aluminum, manganese, chromium, vanadium and molybdenum are defined as parameters as well as a heat treatment parameter (isothermal holding temperature). For reasons of sustainability [1], alloying elements such as nickel and cobalt are not used in the choice of parameters.

The so-called Active Learning Loop(ALL) is used as the central approach for optimizing bainitic steels at the MCL. This is an iterative process at the center of which is a probabilistic material model that generates proposals for new steels and learns from the targeted experimental testing of these proposals. This improves the prediction accuracy of the material model for the next proposal.

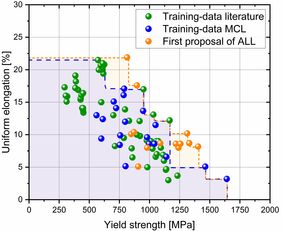

Figure 1 shows the training data used (green and blue dots) and the experimental verification of the ALL 's alloy proposals (orange dots). Each of the data points is associated with a defined chemical composition and defined heat treatment parameters. The ALL 's initial proposals already include bainitic steels with property combinations that go beyond the current state of the art (expansion from blue to orange area). These new experimental data points will subsequently be used to improve the probabilistic model with the help of which the second series of proposals for improved bainitic steels will be carried out. In the course of the current project, a total of four of these proposal series will be carried out and thus new and sustainable high-performance steels will be researched.

Impact and effects

The AI-supported modelling approach presented by the ALL illustrates how material development and optimization can be accelerated in the future compared to classic trial-and-error approaches. It forms the basis for adaptations in the direction of other material classes and optimization tasks for material properties, on which the MCL is working together with its scientific and industrial partners.

[1] Europen Comission: Critical raw materials, https://rmis.jrc.ec.europa.eu/

-

Project coordination (Story)

Dr. Dominik Brandl

Senior Scientist Steel Engineering

Materials Center Leoben Forschung GmbH

T +43 (0) 3842 45922-62

Dominik.brandl(at)mcl.at

IC-MPPE / COMET-Zentrum

Materials Center Leoben Forschung GmbH

Roseggerstrasse 12

8700 Leoben

T +43 (0) 3842 45922-0

mclburo(at)mcl.at

www.mcl.at

Project partners:

• Montanuniversität Leoben, Austria

• Technische Universität Wien, Austria

• The University of British Columbia, Canada

• Institute of Physics of Materials, Czech Republic