With many modern materials, both the composition and the manufacturing process are complex. This results in a huge number of possibilities for improving material properties. At the same time, material production and characterization often demand a considerable amount of resources. The use of artificial intelligence (AI) methods is promising here, but is also limited due to the small number of available data points. It is therefore important to make the best possible use of existing knowledge, both in the form of data and in the form of physical correlations. This is made possible by the platform for accelerated material development called ALPmat, which is being set up at the MCL as part of the MCacceL project. The name ALPmat is derived from "Active Learning Platform for Materials Development".

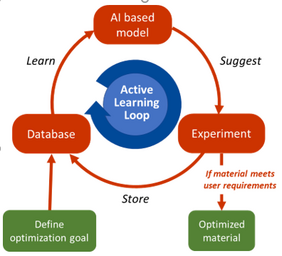

Active learning is an AI method in which an algorithm learns iteratively (see Fig. 1). Once the design goal has been defined, a model is created that describes the existing data and predicts the properties of new data, taking existing knowledge into account.

This model is used to make suggestions for new compositions or process parameters. Based on these suggestions, new materials are produced and characterized, which increases the number of data points. With the increased data set, the model is improved (it “learns” from the new data) and the next iteration is started. This can significantly shorten the development process.

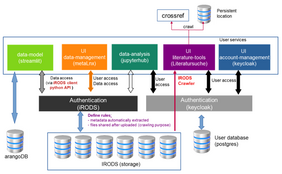

The ALPmat material acceleration platform has to fulfill a number of tasks and requirements. These include the automated upload, storage and exchange of data, including metadata from measurement and simulation, which can then be processed, visualized and fed into the AI algorithms. Moreover, the platform must enable collaboration between many users from the fields of material production, characterization, simulation and data-based modelling. Finally, it must be expandable and meet the latest state of the art in terms of data security. With ALPmat, this is achieved through a modular structure and virtualization on several levels (top image).

Impact and effects

Standardized data including metadata from measurement and simulation can be uploaded automatically and supplemented with digitized literature data. All available data can be easily analyzed and processed. The ALPmat also offers the possibility to evaluate the data using AI-based algorithms, linking the knowledge gained with empirical equations and thus predicting the properties of previously unknown materials on the computer. The experimental processes are mapped on the computer using a data model and each measurement result is clearly assigned to a measured sample and its condition. The data model also makes it possible to describe the relationships between different measurements and sample states.

The first applications for the ALPmat are the improvement of the energy storage properties of perovskite materials for the short-term storage and conversion of electrical energy and the ductilization of high-strength bainitic steels, which provide us with increased safety, e.g. as rock anchors in tunnels. The first iterations have already delivered promising results. The ALPmat will be used in new research projects at MCL and will also be made available to the general public via licensing in the future.

-

Project coordination (Story)

Dr. Jürgen Spitaler

Key Scientist Computational Materials Design

Materials Center Leoben Forschung GmbH

T +43 (0) 3842 45922-70

Juergen.spitaler(at)mcl.at

IC-MPPE / COMET-Zentrum

Materials Center Leoben Forschung GmbH

Roseggerstrasse 12

8700 Leoben

T +43 (0) 3842 45922-0

mclburo(at)mcl.at

www.mcl.at

Project partners

• Know-Center GmbH, Graz, Austria

• Monanuniversität Leoben, Austria

• University of British Columbia, Vancouver, Canada

• Technische Universität Wien, Austria

• KTH Stockholm, Sweden

• Czech academy of sciences, Institute of Physics of Materials, Brno, Czech Republic