The final step in the production of electronic parts is the packaging and wiring of components. During these processes, the finished and tested components are soldered, glued, connected, and encapsulated very often in polymer based materials. All of these steps bring additional loading to the component due temperature treatments and different coefficients of thermal expansion. These loads can either directly lead to the component failure or to permanent deformations and stresses that affect the long-term behaviour of microelectronics components.

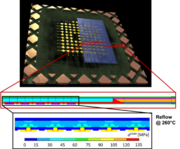

An example of a manufacturing process is the embedding of micro-electronic components in printed circuit boards. The image shows a Si-Chip, which has been integrated into a circuit board by means of a multi-stage embedding process. Each of these steps causes thermo-mechanical stresses. The aim of this study is to predict the stress on the component in order to minimize it by optimizing the production process and the component geometry.

Contact: Elke Kraker