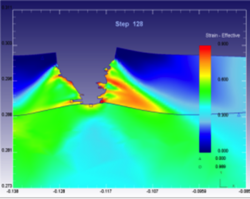

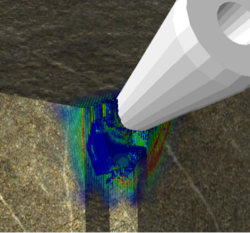

The accuracy of finite element simulation results depends crucially on the underlying model assumptions. An essential modelling ingredient is the description of nonlinear material behaviour, which plays a pivotal role in the simulation of manufacturing processes (e.g., forming, heat treatment, surface post-treatment) and of heavy-duty components during operation.

For describing the material behaviour with respect to, e.g., cyclic plasticity, phase transformations including transformation strains, damage and lifetime, one needs on one hand appropriate constitutive material models which are able to depict the observed physical phenomena correctly and efficiently, and on the other hand the correct model parameters for the material at hand. These parameters are typically obtained by experiments on the macro- and microscales; however, increasing use is being made also of computational ab initio and micromechanics models. MCL is a one-stop provider for all that, conducting theoretical and experimental research in the fields of

- microelectronics components and tools,

- prediction of mechanical properties and residual stresses during manufacturing of semi-finished steel products and components,

- change of mechanical properties due to precipitation and

- hydrogen embrittlement.