Tools optimized by the MCL

"Our speciality is the analysis, development and optimization of tools"

Tools are both a key innovator as well as cost factor in industrial production. The interaction between tool and workpiece always involves contact of different materials under extreme conditions. The goal of MCL’s materials research is to extend tool life and efficiency, making manufacturing processes more cost-efficient, and opening up entirely new methods of production. This creates the basis for using innovative tool developments to process new materials and design new shapes – from small and smallest dimensions to the largest scale.

Processing Beyond Limits

Any change in a material’s form or internal structure also requires profound changes in the manufacturing process – whether a material is suitable for an application or not often depends on the tool used for shaping it. With its expertise in high-strength tool materials, the MCL offers its development, simulation and testing services wherever two different materials come into contact in the manufacturing process. This places the MCL on track to achieve its ambitious goal of becoming the world‘s leading center for tool technology and production.

Materials for Tools

"Ongoing Innovation."

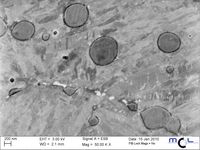

The MCL collaborates with partners to develop innovative materials for tools and coatings based on the characterization of the material's structure and properties:

1. Material development

- Tool steels

- Steels with specific physical properties

- Hard metals

- Nickel and carbon-based tool materials

- Hard and tribological coatings

2. Characterisation of material structures and material properties

Tool Dimensioning and Tool Behavior

"We understand tools from inside out."

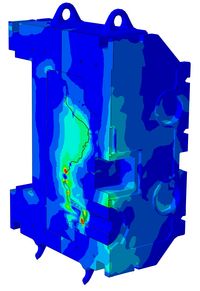

With many years of experience, the MCL can simulate the behavior of all types of tools regarding their physical limits. This enables reliable load calculations and predictions of the service life which in turn create the basis for the efficient planning of process chains and innovative methods of tool optimisation. Additionally, the MCL provides the methods and equipment needed to record the necessary simulation data:

- Knowledge based design of high-performance tools, including material selection

- Damage analysis and calculation of tool life

- Shortening of process chains and cycle times

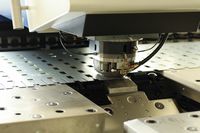

- Simulation of in-service tool behaviour for die casting tools, forging tools, cold working tools, turning, stamping and drilling tools, including inserts, fine blanking tools and tunnel drills

Optimising Tools Through Specific Adaptation to Local Stresses

"Applying the correct properties in the accurate place."

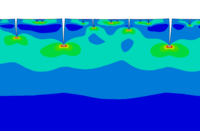

The MCL calculates the tool loads occurring during manufacturing processes to develop concepts for tailoring tool properties to local loading conditions (targeted inhomogeneous tool structure). This includes:

Technologies for adapting material properties to service conditions

- heat treatment

- surface technology (mechanical, chemical and thermochemical)

Prediction of local properties after manufacture

- hardness, toughness and property distributions

Simulation of in-service behaviour and properties of tools with an inhomogeneous structure

- crack formation and growth in inhomogeneous tools

- service life of inhomogeneous tools

Examples

"The tools of our customers and partners are shaping the world."

The MCL provides fundamental research, simulation and experimental results that allow our customers and partners to manufacture tools that redefine the possibilities of production processes.

- PCB micro drills through to tunnel drills of several meters in diameter

- Opening up new manufacturing methods using hard metals

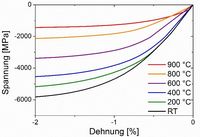

- Development of sophisticated characterisation and testing methods for materials with strengths of more than 8000 MPa even at elevated temperatures