"We understand tools from inside out."

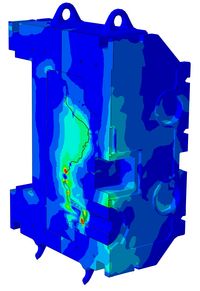

With many years of experience, the MCL can simulate the behavior of all types of tools regarding their physical limits. This enables reliable load calculations and predictions of the service life which in turn create the basis for the efficient planning of process chains and innovative methods of tool optimisation. Additionally, the MCL provides the methods and equipment needed to record the necessary simulation data:

- Knowledge based design of high-performance tools, including material selection

- Damage analysis and calculation of tool life

- Shortening of process chains and cycle times

- Simulation of in-service tool behaviour for die casting tools, forging tools, cold working tools, turning, stamping and drilling tools, including inserts, fine blanking tools and tunnel drills