Matter – the basis of everything that holds it together

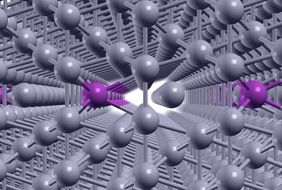

What makes a diamond hard? Why does copper conduct electricity but ceramic doesn’t? How can steel be both hard and yet formable? The answer to all these questions lies in the building blocks of matter – atoms. At the atomic level the power of attraction between the positively-charged atomic nucleus and its negatively-charged electrons binds matter together and determines how materials react to external influences. Ultimately, it is purely the interplay between this "plus" and "minus" which is responsible for creating every different form of material and its properties, such as strength, magnetism or density.

Designing new materials with a computer – the idea is already 90 years old

Ninety years ago, Erwin Schrödinger has formulated a method for calculating the interplay of these particles using the equation which bears his name. In principle, this equation can be used to calculate the properties of all materials, but actually solving the equations proved so complicated that calculating even the simplest of materials was impossible. Walter Kohn formulated a more efficient theory for which he was awarded the Nobel Prize. This theory has helped to advance the calculations further and this, paired with rapid advances in computing power over recent decades, has made working through the equations easier. As a result, it is now possible to predict material properties on the basis of their atomic structure.

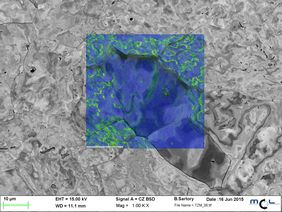

Modern industry relies on reliable calculations and a combination of theory and practice. At the Materials Center Leoben a team of nine young scientists is investigating how so-called atomistic modeling can be used to improve material properties. This requires a fundamental understanding of matter as well as practical experience with the materials. With the aid of state-of-the-art computer programs, co-developed at Leoben, the properties of new materials are calculated in advance. This enables predictions to be made about the basic properties a new material will possess before it is created, for example, how strongly it will expand under increasing temperatures, its optical features, and whether it will exhibit good plastic flow properties.

A wide range of atomistic modeling applications are currently in use at MCL. One research project investigates how foreign atoms attach themselves to the grain boundaries in a variety of metals, and the impact this has on metal strength. Another project explores how diffusion barriers in semiconductor devices work at the atomic level and how they can be optimised. Yet another is concerned with calculating the influence of alloying elements, temperature and magnetism on defects in the atomic lattice. The results will provide the basis for the future design of new steels with exceptional formability.

Impact

The long-term goal of atomistic modeling is to "design" new materials directly on the computer. The aim is to make them particularly hard, corrosion-resistant or exceptionally light – or ideally able to fulfill several criteria at once. This saves expensive and time-consuming development processes involving the creation and testing of many thousands of samples.

In order to achieve the goal of computer-supported predictions of materials and material properties, atomistic modeling methods need to be further advanced, and more closely linked to modeling methods based on other length and time scales.

The MCL is currently working on calculations for metal alloys, on the structure and properties of crystal defects (e.g. lattice vacancies, displacements, grain boundaries) and their impact on physical phenomena such as diffusion, and increasingly on functional properties (e.g. electrical and optical properties).