The accurate simulation and description of multi-phase flows plays an important role in process simulation in order to enhance quality, efficiency and security of production processes. Depending on the inherent process characteristics, different phases (gaseous, fluid, solid) co-exist. Physical and chemical processes like mixing, solubility, heat- and mass-transfer can occur, and have to be modelled adequately.

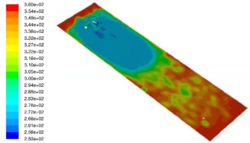

An example of a successful application of multi-phase simulation is the optimization of high-speed wiping nozzles in the continuous hot-dip galvanizing process. The height of the liquid zinc coating is reduced employing a transonic gas-jet. In order to predict the height, a detailed modelling with LES-VOF technique is required, which includes the interaction between the high-speed gas flow and the liquid zinc film. A detailed knowledge of this interaction offers the opportunity to optimize process parameters with respect to uniform coating thickness [Pfeiler2014,Pfeiler2015].

Another application example of multi-phase modelling are spray-processes, like cooling of components or spraying of etching or coating chemicals. The correct modelling of the surface interactions (e.g. wetting of a surface, phase-changes, heat-transfer, chemical reactions …) is of the utmost importance to get reliable results.

![High-speed wiping nozzle in action. The controlled gas-jet yields an optimized coating [Pfeiler2015].](/fileadmin/_processed_/6/b/csm_Simul_FE_Stroemungsmech2_0b686afcf5.png)