Mechanics of Materials

Mechanics of materials is a pivotal area of research at MCL. In this field, one aims on one hand at achieving optimum material properties for specific applications, and on the other hand at accounting as precisely as possible for the complex behaviour of modern materials in finite element simulations.

Our team, consisting of material scientists, physicists and mathematicians, concentrates its efforts mainly on the following topics:

Contact Mechanics

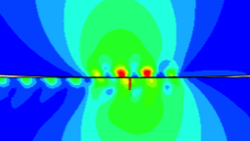

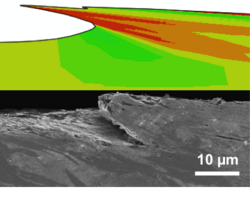

In technical applications, mechanical contact between machine parts or with the environment plays an important role. Typical examples are contact between tools and components (e.g., during forging, blanking or machining), between wheels and rails, or between balls and rings in roller bearings. The local loads at the contact points depend, among others, on the external loading, surface roughness, friction and lubrication conditions, and are extremely challenging for the materials with respect to (rolling) contact fatigue.

Our simulations aim at computing contact conditions and contact loads in order to derive measures for improving the contact conditions on the one and, and on the other hand to provide the basic knowledge necessary for enhancing the contact fatigue resistance of materials and for virtual testing of new materials.

Material Modelling

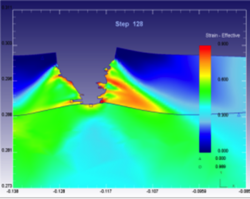

The accuracy of finite element simulation results depends crucially on the underlying model assumptions. An essential modelling ingredient is the description of nonlinear material behaviour, which plays a pivotal role in the simulation of manufacturing processes (e.g., forming, heat treatment, surface post-treatment) and of heavy-duty components during operation.

For describing the material behaviour with respect to, e.g., cyclic plasticity, phase transformations including transformation strains, damage and lifetime, one needs on one hand appropriate constitutive material models which are able to depict the observed physical phenomena correctly and efficiently, and on the other hand the correct model parameters for the material at hand. These parameters are typically obtained by experiments on the macro- and microscales; however, increasing use is being made also of computational ab initio and micromechanics models. MCL is a one-stop provider for all that, conducting theoretical and experimental research in the fields of

- microelectronics components and tools,

- prediction of mechanical properties and residual stresses during manufacturing of semi-finished steel products and components,

- change of mechanical properties due to precipitation and

- hydrogen embrittlement.

Publications

Contact Mechanics

- Daves W., Kubin W., Scheriau S., Pletz M., A finite element model to simulate the physical mechanisms of wear and crack initiation in wheel/rail contact. Wear, (2016)

- Kráčalík, M., G. Trummer, and W. Daves. Application of 2D finite element analysis to compare cracking behaviour in twin-disc tests and full scale wheel/rail experiments. Wear 346, (2016), 140-147.

- Pletz M., Daves W., Yao W.P., Kubin W., Scheriau S.: A wheel set/crossing model regarding impact, sliding and deformation—Explicit finite element approach. Wear 294, (2012), 446-456

- Pletz M., Daves W., Ossberger H.: Multi-scale finite element modeling to describe rolling contact fatigue in a wheel–rail test rig. Tribology International 80, (2014), 147-155

- I. Krajinović, W. Daves, M. Tkadletz, T. Teppernegg, T. Klünsner, N. Schalk, C. Mitterer, C. Tritremmel, W. Ecker, C. Czettl, Finite element study of the influence of hard coatings on hard metal tool loading during milling. Surface and Coatings Technology 304, (2016), 134-141

- R. Ebner, P. Gruber, W. Ecker, O. Kolednik, M. Krobath, G. Jesner, Fatigue damage mechanisms and evolution near cyclically loaded edges, Bulletin of the Polish Academy of Science: Technical Sciences, Vol. 58, No. 2, (2010)

Material Modelling

- Drexler, H. Maderbacher, E. Povoden-Karadeniz, H.-P. Gänser, W. Ecker, B. Oberwinkler, A. Fischersworring-Bunk, Yield stress evolution in Inconel 718 samples under standard heat treatment process conditions of turbine disks. Proceedings of the European Conference on Heat Treatment 2015 & 22nd IFHTSE Congress (2015)

- M. Fischlschweiger, W. Ecker, R. Pippan, Verification of a continuum mechanical explanation of plasticity-induced crack closure under plain strain conditions by means of finite element analysis, Engineering Fracture Mechanics 96 (2012) 762-765

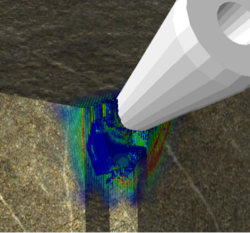

- M.J. Mikl-Resch, T. Antretter, M. Gimpel, H. Kargl, G. Pittino, R. Tichy, W. Ecker, R. Galler, Numerical calibration of a yield limit function for rock materials by means of the Brazilian test and the uniaxial compression test, International Journal of Rock Mechanics and Mining Sciences 74 (2015) 24-29

- M. Schemmel, P. Prevedel, R. Schöngrundner, W. Ecker, T. Antretter, Modelling of phase transformations and residual stress formation in hot-work tool steel components, , In: Proceedings of the European Conference on Heat Treatment and the 21st IFHTSE Congress, May 12th-15th, 2014, Munich, Germany, (2014) 285-292

- Ishmurzin, W. Ecker, M. Krobath, M. Orthaber, S. Marsoner, T. Antretter, The cyclic elasto-viscoplastic behavior of a high-speed steel under forging conditions - Experiments and simulations, Procedia Engineering 10 (2011) 1991-1996

- W. Ecker, T. Antretter, R. Ebner. Calibration and validation of an elasto-viscoplastic material model for a hot work tool steel used in pressure die casting dies. Key Engineering Materials, 345-346 (2007) 685–688