- Qualitative and quantitative X-ray Phase analysis (25°C to 1400°C)

- Determination of retained austenite by X-ray analysis (acc. to ASTM E975-03 or by Rietveld method, including depth profiles)

- X-ray phase and structure analysis of thin surface films

- Determination of fibre textures in coating systems (25°C to 900°C)

- Determination of textures in metallic materials

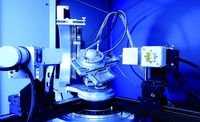

- Determination of process induced residual stresses on surfaces by X-ray analysis (25°C to 900°C)

- Determination of residual stress depth profiles on specimens and components (e.g. gear components)

- Mobile on-site residual stress measurement on large components or materials

- Measurement of time-temperature-transformation and precipitation diagrams (continuous and isothermal, CCT, TTT, TTA)

- Chemical material analysis by arc spark optical emission spectrometry* and X-ray fluorescence analysis

- Measurement of carbon and nitrogen depth profiles on thermochemically treated steels

- Chemical depth profile analysis of thin films (e.g. nitride / carbide / oxide films)