Compared to steels hard metals exhibit a considerably higher resistance to abrasive wear and plastic deformation. This makes them a good choice for the use as tool materials in metalworking tools that have to endure high cyclic loads. The fact that also these very resistant hard metals undergo damage in industrial cutting applications, requires detailed studies of their failure behaviour.

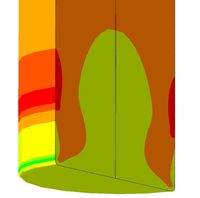

For this purpose, detailed computer simulations of cutting processes such as milling or fine blanking are performed. This helps to quantify the tool loads that act in the most highly loaded tool zones in which tool failure initiates. The acquired information leads to knowledge-based improvements of the tool geometry, the required surface finish and the tool's inner architecture.